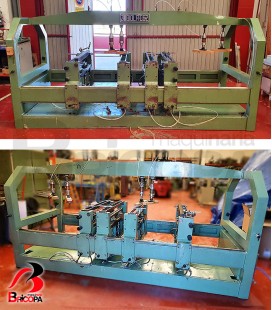

CNC WORKING CENTRE PROFIT H300 16.53

Working area X = 5300 mm, Y = 1280 mm, Z = 250 mm. Horizontal drill unit with 4 spindles. Vertical drilling unit with 12 vertical drilling spindles. 12 position linear changer on the left hand side

CNC MACHINING CENTRE PROFIT H300 16.53 FORMAT-4: The increasing demand for custom-made products in furniture, door and window production is providing a challenge for all workshops, above all smaller companies: Diverse profiles have to be produced with flexibility, efficiency and in several thicknesses, to be able to keep up with larger manufacturers in the market. With a large dimensioned working field in Y, the profit H300 offers almost limitless possibilities in panel and solid wood processing. Standard and special applications can be flexibly covered with the wide range of products and numerous configuration options available. To ensure a productive work process, the machine and software must be in perfect harmony, numerous interfaces from various suppliers often make this interaction difficult. With the "everything from a single supplier" solutions from Format-4 the customer will receive a perfectly matched complete package for the highest of requirements.

- The drilling head covers the whole working field, both horizontally and vertically

- Up to 36 tool positions, for every challenge

TECHNICAL DETAILS

Working area:

X= 5300 mm

Y= 1580 mm

Z= 250 mm (Passage height from console height)

CNC machining centre with gantry design: The machine chassis of the Profit H300 15.33 is made from thick walled electrically welded shaped tubes.

Linear guides:

- Y-axis guiding system:

Positioning is carried out by recirculating ball bearings running along hardened and polished linear guides. The Y axis is positioned by a polished recirculating ball spindle. - Guiding system Z-axis:

Positioning is carried out by recirculating ball bearings running along hardened and polished linear guides. The Z axis is positioned by a polished recirculating ball spindle.

Automatic central lubrication system: the lubrication is applied as and when required to the guide carriages of the X, Y and Z axis as well as the bearing spindles in Y and Z. Lubrication is carried out automatically after a preset time.

Secure workpiece support - precise results: The dual circuit vacuum console table with manual suction pod positioning prevents the inadvertent shifting of the suction pods as the workpiece is placed on them. Various different Format-4 vacuum pods can be used to secure every conceivable workpiece design quickly and reliably.

Positioning display of consoles and vacuum pods: the workpiece, consoles and vacuum pods are all displayed in the CNC board simultaneously. This guarantees, that the workpiece is securely positioned and that there can be no collision between the tool and vacuum pod. The exact position of the vacuum pods on the consoles is shown accurately using a laser.

Workpiece cylinder stops at “double zero point” (second fence row): Additional to the workpiece cylinder stops for the “standard-zero point” is the second fence row found in the front part on every work bed, particularly useful for processing large workpieces. (Available as an option with the H20)

Workpiece stops for veneered panels: In addition to the standard workpiece cylinder stops, there are additional stops specifically developed to machine veneered panels with projecting veneer or laminate.

Chip conveyor for waste pieces and residual chips and shavings: For the removal of offcuts and chips from the machine chassis. At the end of the conveyor belt they are separated and then extracted. The remaining pieces are collected in a container.

Drilling head DH 16 4H 2S: Vertical drilling unit with 12 vertical drilling spindles. 7 spindles in the X direction and 5 in the Y direction.

Horizontal drill unit with 4 spindles, 2 in the X axis and 2 in the Y axis. All of the spindles are powered and can be used individually.

The main spindle: With a motor power of 12 to 15 kW with up to 24.000 rpm and inverter controlled, the main spindle motor is more than capable to tackle any task. The motor is fixed directly on to the carrier unit in the Z-axis. The highly precise vertical guiding of the moulder motor is guaranteed by two vertical guide tracks. The HSK F63 tool clamping is carried out automatically. The clamping pressure of the tool is controlled by sensors and the operation safety guaranteed. The tooling housing is cleaned pneumatically.

The C-axis is optionally as the available fourth axis and is interpolating (360°) with a compressed air interface for the units.

Workpiece feeding rails: Loading supports assist in the simple loading and unloading of large or heavy workpieces. A major advantage is that they enable you to operate the Format-4 machining centre alone.

Reinforced loading supports with a higher load capacity are also available as an option.

Chipping deflection plate: A chip deflector mounted to the spindle controlled by the C-axis enables the unlimited use of existing tools. When machining the edge of a workpiece, dust and chips are directed into the extraction port.

Dust extraction hood: In two steps, the extraction hood fully automatically adjusts to the workpiece height. The dust volume as well as the noise volume are thereby significantly reduced.

Length measurement system: Setting the parametres of your tools made easy: every tool length is stored in the tool database accurately to one hundredth of a millimetre.

Panel activation: Specially designed for use with compressed air controlled frame clamp systems, this function offers new possibilities and enormous clamping strength when it comes to the processing of solid wood. The ability to be able to deactivate the consoles individually makes it possible to remove waste material without having to release the vacuum holding the workpiece. This ensures that the workpiece stays in exactly the right position for the next working process (inner profiles etc.).

12 position linear changer on the left hand side: The linear tool changer with 12 different tooling positions (including 1 aggregate) mounted on the left hand side of the machine offers unlimited machining diversity.

18 Position Rotary Tool Changer mounted to the outrigger:

Option: The rotating changer with 18 tool positions is mounted at the back of the outrigger and moves with the outrigger along the X-axis. The 18-position rotating tool changer, keeps tooling changing times to the bare minimum making the Format-4 machining centre even more efficient!

Pick-Up Tool Changer: Tool changer for 4 milling tools or aggregates, mounted to the gantry ensures quick tool changes even when working in pendulum operation.

12 position linear tool changer:

Optionally up to 2 linear tool changers each with 12 tool positions can be mounted at the back of the machine chassis. This then offers quick tool changeover and more than adequate space for tools and aggregates.

Spraying unit and compressed air cleaning of the tooling: All of the vacuum pods positioned on the CNC will be shown including any possible collisions.

Optionally a nozzle can be mounted for the minimal lubrication or air cleaning of the tools.

To request information about this product, you can do so in the following ways.