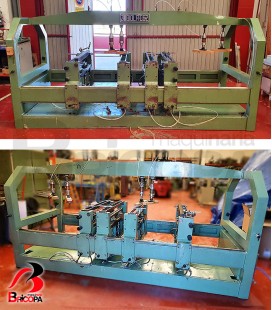

CNC NESTING WORKING CENTRE PROFIT H08 13.25 PROFESSIONAL

Working area X= 2500 mm, Y= 1250 mm, Z= 85 mm. Vertical drilling unit with 8 vertical drilling spindles. 8 position tool changer. Milling spindle has an HSK-F63 tool holder 10 kW

- Technical description

- Download brochure

- PROFIT H08 13.25 PROFESSIONAL FORMAT-4 VIDEO

- Ask for information

CNC NESTING WORKING CENTRE PROFIT H08 13.25 PROFESSIONAL FORMAT-4: The profit H08 from Format-4 is the CNC machining centre for professional nesting applications in the smallest of spaces. Designed specifically for universal purposes, the high precision and productivity achieved when processing varying materials particularly impresses about this profit making all-rounder.

Quick and simple: standard panel processing in the smallest of spaces

- Uncompromised efficiency for wood, plastic, aluminium composite panels and plasterboard

- Bridge design with 'Gantry' drive: quick, precise and low maintenance

- Matrix table with optimised grid geometry for perfect nesting results

- Optimum operational safety guaranteed by light beam sensor control and emergency stop

- Specially designed for each other: Machines and software from one supplier!

- Format-4 Woodflash Control: simple program creation, numerous automation possibilities and highest level of safety due to constant program control.

- Barcode connection for networked workshops

TECHNICAL DETAILS

Working area: X= 2500 mm, Y= 1250 mm, Z= 85 mm

‘Professional' equipment package for maximum productivity and complete flexibility: In the Professional package the high performance milling spindle has an HSK-F63 tool holder which together with a 10 kW motor power and 24.000rpm, delivers perfect results even when processing difficult to work materials.

Automatic measuring system of the tool length: Setting the parametres of your tools made easy: every tool length is stored in the tool database accurately to one hundredth of a millimetre.

Bridge design with 'Gantry' drive: quick, precise and low maintenance: The dual side driven gantry on the profit H08 guarantees maximum precision and repeatability. The rack and pinion drive in the X and Y direction ensures for maximum traverse speeds for the shortest processing times and tool changing times.

Perfect nesting with the FORMAT-4 matrix table: The matrix table with optimised grid geometry allows the full surface support of workpieces of all designs and sizes and guarantee their exact positioning. Reference fences mounted directly to the table offer additional support when optimising off-cuts and can be optionally monitored with collision prevention sensors.

The FORMAT-4 Vacuum System - three options for every requirement: With three vacuum systems, the FORMAT-4 profit H08 offers a high level of flexibility. 180, 250 or even 500 m³/h vacuum power as well as 6 or 8 manually controllable vacuum fields guarantee perfect adaption to different materials and workpiece sizes.

Format-4 software - programming is child's play: With the software that has been especially developed for the machining centre, Format-4 offers a reliable complete package that is of a different class.

2 different control variations are available to ensure professional CNC processing:

'Compact-control' makes it possible to run ISO-codes and Woodflash programs from external software solutions in conjunction with the Format-4 machining centre.

'Woodflash-Control' is the tried and tested Felder in-house developed software solution for simple and efficient programming. Quick program creation and high automation possibilities, a variety of nesting applications as well as barcode connection for networked workshops guarantees efficient programming and high productivity.

Additional sealant for extreme operating conditions: Heavily dusted materials can increase the amount of maintenance required on your CNC machining centre massively. Additional sealant on the guiding carriage and linear guides closed off by brass caps guarantee a noticeably higher operating life, even with heavy use.

3D-Milling machine: Simplest 3-axis application with impressive results. There is no limit to your creativity.

Engraving: Your future field of application is not only limited to wood. Special equipment features also allow the processing of Alucobond.

Screw taps: Metric threads or fine threads. Simple programming - perfect results.

Automation with unloading unit including electromotive offloading pusher: With the automatic unloading unit for finished workpieces you can take advantage of shorter processing cycles giving you higher productivity and greater yield.

To request information about this product, you can do so in the following ways.