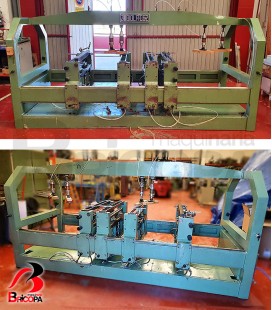

SANDING MACHINE MFA 10 HEESEMANN

Sanding machine MFA 10 HEESEMANN is ideal for sanding high gloss surfaces or calibrating solid wood panels. Sanding width 1350 – 1600 m, 5-25 m/min feed speed, sanding units up to 6. Flexibility to be equipped for all applications

SANDING MACHINE MFA 10 HEESEMANN: the MFA 10 is a real all-round talent for all sanding tasks. It can be flexibly equipped for all conceivable applications with up to 6 calibrating, sanding and brush units in accordance with customer requirements. The MFA 10 is available as a top sanding machine and as a bottom sanding machine.

Be it for sanding high gloss surfaces or calibrating solid wood panels: the MFA 10 can be configured optimally for any task. With its extremely robust design for a long service-life it is suitable for multishift operation in surface finishing lines. As a standard the MFA 10 is equipped with the EnergyManagement-System.

The MFA 10 is available in sanding widths of 1.350 mm and 1.600 mm.

MACHINE DATA

Machinery base: working height 880mm, working width 1350 mm – 1600mm

1 unit: Length(mm) Max. 2340

2 units: Length(mm) Max. 2940; Feed speed (m/min) 3-15

3 units: Length(mm) Max. 3540; Feed speed (m/min) 5-25

4 units: Length(mm) Max. 4140; Feed speed (m/min) 8-40

5 units: Length(mm) Max. 4740

6 units: Length(mm) Max. 5340

AVAILABLE SANDING UNITS

Contact roller unit: the Heesemann contact roller units are offered with steel rollers as well as with rubber-coated rollers in different Shore hardnesses. Both types are deliverable with different roller diameters. The contact roller unit can be equipped with different kinds of hold down elements depending on the requirements of the application.

Cross Belt sanding unit: for wooden surfaces the cross sanding method achieves the world-wide accepted best sanding result. The work pieces are sanded crosswise to the grain direction first and are afterwards sanded in direction of the grain with one or more sanding units.

Longitudinal sanding unitwith an optimized distance between the lower driven drums allows a large amount of a freely suspended sanding belt for a highly flexible pressure onto the work piece. This way a smooth sanding and

high working speeds are achieved.

RUT Disc brush unit: the RUT disc brush unit consists of 19 respectively 21 disc brushes. Their arrangement allows the sanding of contours with unparalleled quality. All areas of the work piece are evenly sanded in every direction.

Brush units: Heesemann sanding machines have available a wide variety of brush units with different bristles and abrasives for sanding and structuring. The brush units can be mounted on an angle to the feed direction or can be equipped with oscillation.

OSR Orbital sanding unit: when sanding frames and other work pieces with different grain directions sanding against the grain direction cannot be avoided. The generated scratch patterns are very evident, especially when dark stains are used. The Heesemann orbital sanding unit removes these scratches and leaves a clean surface with no visible scratches.

EFFECT SANDING: usingsurface sanding machines equipped with at least one cross sanding unit and one longitudinal sanding unit you can achieve stunning sanding effects. This is a brief description of what you can achieve:

- Rough saw cut pattern

- Scattered depenings

- Vintage look

To request information about this product, you can do so in the following ways.