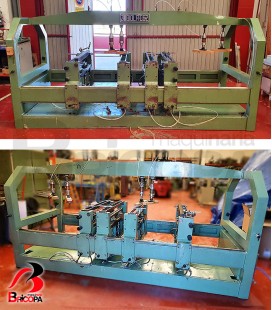

EDGEBANDER MACHINE G 680 FELDER

EDGEBANDER MACHINE G 680 FELDER: Installation length: 3995 mm. Edge thickness: 0,4–6 mm (8 mm). Workpiece thickness: 8–60 mm. Complete machining of edges. Tool free changing of the gluepot with quick change system.

G 680 FELDER

New machinery

EDGEBANDER MACHINE G 680 FELDER

- Individual finishing unit options to suit the customer's requirements.

- Corner rounding unit.

- Perfect results with the flush and radius trimming unit.

- Solid pressure area with three pressure rollers.

- Premilling unit with 2 diamond tipped spindles rotating in opposite directions.

- “Quick-Set-System” for quick and precise adjustment of different edging material.

- Control panel with LCD display.

TECHNICAL DATA

Electrical setup

- 3x 400 V.

- 50 Hz.

Premilling unit

- Premilling unit centrally controlled – can be disengaged.

- Adjustable cutting depth (mm): 0-2

- Tool diameter (mm): 60

- Max. processing height (mm): 60

- No. of asymmetrical diamond tipped V-cut milling units: 2+2

- Rpm: 12000

- Power (kW) of each motor: 1,1

Working dimensions

- Edge thickness min–max. (mm): 0,4-6,0(8).

- Work piece thickness min–max. (mm): 8-60

- Min. workpiece width (mm): 70

- Min. workpiece length (mm): 140

Units

- Coiled edge band feed support plate Ø 800 mm, for PVC/ABS.

- Edge feeding is automatic for edge materials with a thickness of 0.4–6 mm, strip glue in separate feed.

- Teflon coated 2 kg capacity glue pot with quick change system, glue application via an adjustable glue roller ,~ 250lfm per 1kg granules on a 19mm plate.

- Guillotine trimming unit for the precutting of PVC/ABS edgeband material 0.4–3.0 mm thick.

- Pressing unit is mechanically pre-stressed, 1 straight pressure roller and 2 conic additional pressure rollers, adjustment by means of an edge portion.

- End trimming unit with 2 independant motors, each with 0.2 kW and 12,000 rpm, both manually tiltable between 0°–10°.

- Multifunctional milling unit, 12,000 rpm, 0.50 kW, radius milling, flush milling, chamfer milling for thin edges, adjustment by means of edge section.

- Corner processing unit for soft and post-forming workpieces for processing front edges (edge thickness min.–max. 0.4–3.0 mm, max. workpiece height 45 mm, min., workpiece length 270 mm).

- Tooling for 2 mm radius.

Operation

- Operating panel with LCD display and keypad.

Through feed

- Workpiece chain feeder.

- 11 m/min feed speed (~ 420lfm/h).

- Extensible workpiece support.

General

- Extraction connector Ø in mm: 120+ 2x80

- Weight kg (with standard configuration): 990

- Length in mm: 4550

To request information about this product, you can do so in the following ways.

+34 983 40 19 42

+34 637 771 218