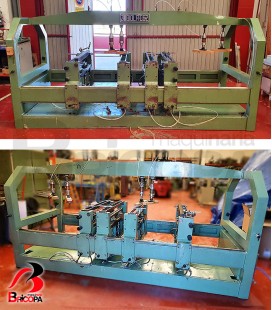

EDGE BANDERS TEMPORA F600 60.12 E-MOTION FORMAT-4

EDGE BANDERS TEMPORA F600 60.12 E-MOTION FORMAT-4, allows a thickness of edges of 0.4 to 12 mm with a thickness of the piece from 8 to 60 mm. Automation: e-motion. Complete machining of edges. Changeable tail containers with quick change system without tools.

F600 60.12 E-MOTION FORMAT-4

New machinery

EDGE BANDERS TEMPORA F600 60.12 E-MOTION FORMAT-4

- 3 spaces for finishing units.

- Corner processing unit (Option: 2 motor corner rounding unit).

- Multi-functional trimming unit.

- End trimming unit with 2 independant saw units.

- Pressure unit with a pressure roller and 2 conical post-pressure rollers.

- Premilling unit with separately controlled diamond milling cutters for chip free glue joints.

- Control panel with a swing away 10.4" colour touch screen.

TECHNICAL DATA

Electrics

- 3x 400 V motor voltage, 50 Hz motor frequency

Working Dimensions

- Min. workpiece width (mm): 70

- Min. workpiece length (mm): 140

- Min. workpiece height (mm): 8

- Max. workpiece height (mm): 60

- Processing of 0.4–3.0 mm coiled material.

- Processing of 0.4–12 mm strip material.

Units

- "E-motion plus" control with 10.4” Touch Screen display with integrated maintenance software and network connection available.

- Solid steel machine chassis.

- Pull-out workpiece support – to assist in the processing of larger workpieces.

- Motor driven adjustment of the workpiece feed pressure rollers with 2 offset lines of rollers for equal pressure distribution on the workpiece.

- Chain feeder with a speed of 12 m/min and rubber grip pads, for maximum grip on the workpiece.

- 770 mm diameter workpiece support roller, running on ball bearings.

- Feeding guide with rollers for processing fragile material.

- Premilling unit with two 1.5 kW independant motors running at 12,000 rpm and diamond tipped cutters, motor driven positioning of the depth of cut between 0–3 mm, 2 diamond tipped cutters included (Ø= 80 mm, H= 49 mm, Z 2+2).

- Edge feed for coiled and strip material 0.4–12 mm thick, with edge presence recognition via an infra-red sensor.

- Guillotine trimming unit for the precutting of PVC/ABS edgeband material 0.4–3.0 mm thick.

- Teflon coated gluepot with 1.5 kg capacity, glue applied using a fine-adjustable glue roller and quick change system as well as monitoring of the heating cartridge.

- Pneumatically feed-controlled glue unit.

- Motor driven positioning of the pressure unit with 1 large motor driven roller and 2 conical rollers operating pneumatically.

- End trimming unit with 2 independant motors, each with 0.50 kW and 12,000 rpm, both pneumatically tiltable between 0°–15°.

- Multi functional trimming unit for radius and flush trimming and bevel trimming of thin edges with 2 independant motors, each with 0.75 kW and 12,000 rpm, motor driven positioning of the edge thickness adjustment and pneumatic disengage function via the control panel.

- Corner rounding unit for soft- and post forming pieces for processing edges of between 0.4 and 3.0 mm in thickness and 10–60 mm in height.

Finishing Units

- 2-axis, motor-driven, position-controlled radius trimming unit incl. pneumatic reverse function.

- Buffing unit with 2 motors.

To request information about this product, you can do so in the following ways.

+34 983 40 19 42

+34 637 771 218