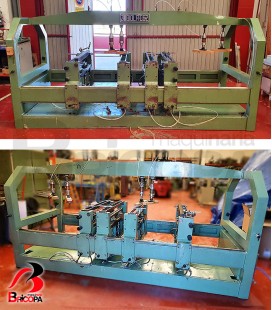

MULTIPLE BORING MACHINE SYSTEM 23

The single head multi boring machine SYSTEM 23 has 23 spindles, with a distance between the 1st and the last one of 704 mm, max boring depth 65mm. Max. working piece mm.960x3000x60

Single-head Boring Machine for Horizontal and Vertical Drilling mod. BORING-SYSTEM/23 BS 23

- Pneumatic head-rotation from 0 to 90 degrees with lock and stop reference in any intermediate position.

- Spyral system, programming and boring depth adjustment

- Safety clamps allows a prompt setting on panels without any adjustments

- Quick and precise setting-up

- High-quality end products

- Safety devices

TECHNICAL DATA

No. of spindles (lft red - rt black) 23 (11 - 12)

Interaxis between spindles 32 mm

Interaxis between first and last splindle 704 mm

Max boring depth 65 mm

No. of clamps 2

Max dimensions of the working piece960 x 3000 x 60 mm

Max height of clamps from working table 65 mm

No. of motors 1

Motor power 2 HP (1,5 kW)

Motor r.p.m. (50 Hz) 2800 rpm

Working air pressure 6-8 bar

Standard air pressure consumption 10 l/cycle

Dust suction diameter 80 mm

Overall dimensions 1315 x 960 x 1265 mm

Height of the working table 860 mm

Package dimensions 1070 x 950 x H 1030 mm

Net/gross weight 265 / 300 kg

PATENTED SPYRAL SYSTEM Programming and boring depth adjustment in horizontal and vertical positions for standard drilling of the following lengths: 57,5 - 70 - 77 - 85 - 105 covering the full length range necessary for any type of operation.

This PATENTED reference system easy and innovative allows a quick and exact setup of boring depth with the following operations:

- choose the type of drill

- decide boring depth readable directly on the scale

- turn the spiral positioning the transparent index on the required depth

- lock the spiral with the handle

PATENTED SAFETY CLAMPS - Our clamps allow a prompt setting on panels of any dimension without any adjustments just pulling up the front grip.

- Clamp diameter is 60 mm

- Clamp pressure is Kg. 90 at 6 atm each.

- The machine has got a THRUST METER, a safety device ensuring the minimum working pressure.

Our SAFETY clamps have been studied to prevent the crushing of the operator's hand.

The maximum height of the clamp from the table is 65 mm.

ADJUSTABLE FENCES ON THE TABLE. Adjustable reference fences on the table guarantee precision dowel boring even out of square cut panels.

This feature is essential in order to get precise work.

DIGITAL COUNTER for DECIMAL adjustment of fence shifting on the table (excursion 34 mm). This system, quick and exact, allows the adjustment of any drilling distance and the symmetric positioning between the 2 fences.

Head with 23 spindles, 32 mm system with quick change chucks. The useful space between the head and the working table allows easy access of the operator for tools change.

Hardened and ground steel, studied and produced to allow a quick and precise clutch of bushes.

Digital counter (DECIMAL) for the adjustment of the drills height from the table.

Pneumatic piston for head tipping.

Drilling capacity with tools maximum diameter 40 mm for hinges with chaser in 3 positions. Additional positions can be reached moving the head 40 mm away from the chaser.

Innovative and reliable system of head rotation from 0 to 90 degrees with lock and stop reference in any intermediate position.

Pneumatic head tipping.

FRONT ELECTRIC DRIVES. All drive are located on the machine front side with easy access. ELECTRIC PANEL according to CE safety regulations with: no voltage release, magnetic switch protecting the motor, low voltage release.

WORKING TABLE. Working table composed by 2 sides, steel reference table and MDF working table scratchproof coating. The ergonomic shape of this table and its material make it easier to position the panel and avoid making any scratches.

With this optimizing crosscut saw just rest the wood on the in-feed conveyor to increase productivity considerably, reduce staff usage to a minimum, and improve wood yield.

To request information about this product, you can do so in the following ways.