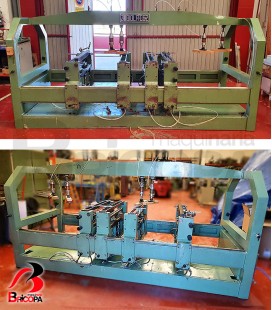

MULTIPLE BORING MACHINE EVOLUTION 1000

The CNC automatic boring machine SYSTEM EVOLUTION 1000 controls 4 axis. Max. dimensions of the workpiece., min. 300 x 120 x 8 mm. Front and back panel unloading.

MULTIPLE BORING MACHINE EVOLUTION 1000 MAGGI

CNC automatic boring machine - accurate drilling from underneath with automatic operator return.

Front and back panel unloading.

STANDARD EQUIPMENT

• Integrated control

• Industrial PC Windows XP Embedded, developed by CNI. 15” colour monitor, CD, keyboard and mouse.

ILENIA CAD -CAM 4 software. USB connection.

• Panel supports forward and backward (1200x400 mm)

TECHNICAL DATA

Max. dimensions of the workpiece: 3200 x 1020 x 50 mm

Min. dimensions of the workpiece: 300 x 120 x 8 mm

Interaxis between spindles: 32 mm

Diameter max boring: 35 mm

N° controlled axes: 4 (x, y, z-, w)

Max boring depth: 50 mm

N° controlled axes x: 42 m/min

N° controlled axes y: 42 m/min

N° controlled axes z-: 10 m/min

N° controlled axes w: 5m/min

Spindle-rotation speed: 3200 rpm

Total Power: 3 Kw

Working air pressure: 6-8 bar

Standard air pressure consumption: 20 l/cycle

Overall dimensions: 2200 x 1500 x 1250 mm

Height of the working table: 900 mm

Net/gross weight:1200 / 1350 kg

To request information about this product, you can do so in the following ways.