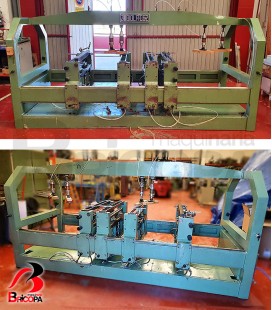

USED GLUE DIMTER PROFIPRESS C2500 WEINIG

USED GLUE DIMTER PROFIPRESS C2500 WEINIG

This glue of second hand in continuous passage, is ideal for gluing boards of solid wood and glued the parts of the frames of the doors.

WOOD DIMENSIONS FOR WORKING

- Average width of wood for pre-frames exterior part: 18mm

• Width min / max of wood for pre-frames exterior part: 15-20mm

• Minimum height of gluing interior and exterior parts: 30-46mm

• Average height of gluing interior and exterior parts: 36mm

• Production of pre-frames exterior parts: 2x900mm-1200mm

• Production of subframes internal parts (possibly butt stop): 400/710/1400 / 2100mm

• Production of pre-frames middle parts: 2200mm

• Pressure strength specified for softwood: up to 0.8N / mm2

• Maximum bend of the boards in all directions: 10mm / m

TECHNICAL DESCRIPTION

1. Feeder for transverse transport I

- External parts of singing.

• Feeding through push plate.

• Speed up to approx 260m / min

• Longitudinal transport always of 2 tables by pusher with servomotor.

• Application of glue only on one side.

• The pair of boards will be positioned in front of the pusher.

2. Feeder for transverse transport II

- Interior width: 40-100mm.

• Interior height: 30-45mm.

• One long or 2-3 short lengths.

• Feed by transport chain up to the stop.

• The outer and inner parts will be positioned in front of the press pusher.

• The press pusher can insert the parts (2 outside and one inside) simultaneously

POSITIONS

• Position 1: Transverse transport I

- The outer parts are running in the edge application.

- Transport by angular station and to the thrust plate to enter 2 table simultaneously.

- 3 chains, each 2m long.

- Pusher driven with servomotor.

- The thrust plate moves upwards for the return travel.

- The boards are put on edge and are maintained like this by rotating brushes.

• Position 2: Automatic queue application

- With tail nozzle and control valve.

- With photocell for start and stop of the tail application

- Glue pressure min 20 bar.

- Includes two tail pumps I and II that are suitable for one component PVAC glues.

• Position 3: Transverse transport II

- Function for gluing several board widths, for placing and inserting the individual tables by the angular station and by upper rollers operated in the gluing station or in the pre-collection station.

- Function for interior parts for the production of '' stiles ''.

- It has 2 transversal chains of approximately 3 meters in length, separation by upper rollers and lower tilting rollers, driven, that move upwards. Input speed max. 150m / min.

• Position 4: Pre-storage station

- For the storage of short lengths, butt stop.

- It has suppression rollers and tilt stop.

- Length: approximately 2.5 meters.

- Width: 150mm

• Position 5: Automatic tail application

- With tail nozzle and control valve.

- With photocell for start and stop of the tail application

- Glue pressure min 20 bar.

- Includes two tail pumps I and II that are suitable for one component PVAC glues.

• Position 6/7: Introduction area

- For storage of 2 edge boards, on the right side and one section on the left side.

- Introduction by heavy pusher of a complete frame in the heated press bench.

- Feeding of equal widths, table by table, in the pressing bench.

- Heavy thrust unit, pneumatically controlled, pressure force up to 12t = 120KN.

- Input chain with multiple links, width 200mm.

• Position 8: Press bench, 12m long.

- Higher backlash elements, hydraulic, to maintain the gluing pressure after feeding.

- Upper and lower heating pipes ensure complete heating of the joints.

- Hydraulic friction beams ensure glue pressure against the thrust unit.

- Press bench length: 12m

- Top pressure backlash element 18t = 180KN

- Press friction beam max 12t = 120KN

- Upper and lower heating pipes will be connected to the existing heating.

CE mark

Subject to prior sale. Characteristics for information only. The technical details are not legally binding. Contact us for further information.

To request information about this product, you can do so in the following ways.