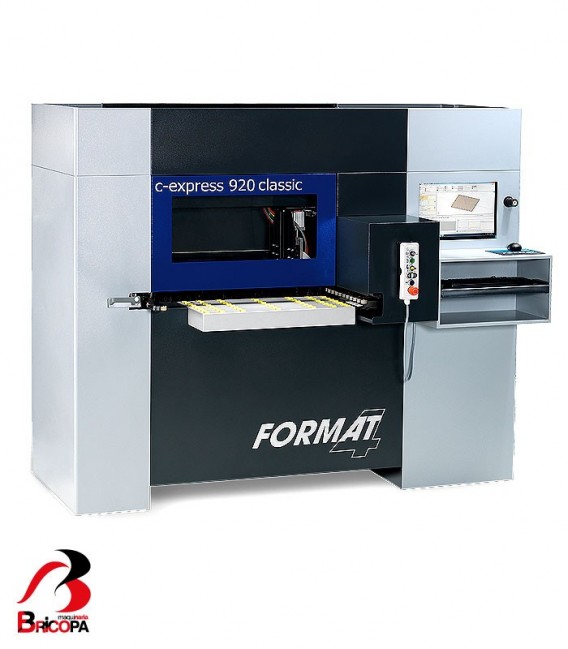

CNC WORKING CENTRE C-EXPRESS 920 CLASSIC

Cnc machining centre in just 3.4 m². 15 drilling spindles, 9 horizontal, 6 vertical spindles, and 1 slot cutter on the X-axis.

CNC WORKING CENTRE C-EXPRESS 920 CLASSIC: the new c-express 920 classic Format-4 CNC drilling and milling centre, carries out all repeat drill and simple milling work efficiently and precise, all in record time. Developed with the smaller workshops in mind, the c-express 920 classic offers a sensational price/performance ratio. Uncompromised development at Felder ensures you profitable CNC productivity. At the touch of a button, repeat drilling work programs can be loaded and reused. This ensures that CNC controlled cabinet production is a profitable option for every workshop, regardless of space constraints

ADVANTAGES

- Compact CNC processing in just 3.4 m²

- High precision 15 spindle drilling head for maximum flexibility

- Horizontal processing of the workpiece ensures a constant zero point

- Simple programming without the need to take the workpiece thickness into consideration

- Grooving saw unit as standard for the processing of back panels or contruction connections

- Modern laser measuring technology ensures highest measuring precision

TECHNICAL DETAILS

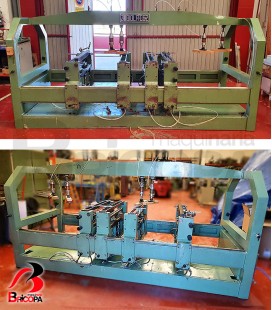

The CNC drilling and milling head

The c-express 920 classic is equipped as standard with a DH15 6H 1S boring head. The total of 15 drilling spindles can be equipped with tooling as required for the work to be carried out. The grooving saw aggregate is included as standard and enables the cutting for back panels or construction connections.

- 9 Vertical spindle

- 6 Horizontal spindles

- 1 slot cutter on the X-axis

Spindle

One of the specification options on the machine is the milling aggregate. The tooling is clamped using an ER32 chuck. Changing of the tooling is carried out manually. This aggregate is used for the routing of cutouts, pockets, grooves and rebates.

Moulding

The milling unit can be used for 3 sided reference cuts as as well as for milling forms within a workpiece. The workpiece has to be positioned at a right angle to the machine.

Measuring technique

Modern measuring technology guarantees the highest measuring precision. An Encoder (distance measuring system and laser) measures the exact length of the workpiece. This ensures that construction connections (used predominantly in cabinet construction) can be done without any overhanging material.

Simple programming and operation

The Format-4 control unit was developed specifically for wood processing machines to drill, mill and saw. A graphical user interface serves to operate the controls (self-explanatory with symbol illustrations).

The programming software „Wood-Flash“ enables quick and easy programming of the workpieces. The 19“ LCD colour monitor, clearly and simply displays all of the processes to be carried out on the workpiece.

As an option it is possible to link the machine with the cabinet programming software Flash 3D, that guarantees an even more rational processing of customer orders.

To request information about this product, you can do so in the following ways.