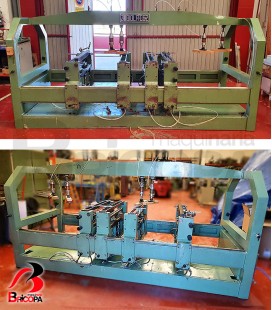

CNC NESTING WORKING CENTRE PROFIT H10 19.38

Working area X= 3720 mm, Y= 1860 mm, Z= 105 mm. Vertical drilling unit. 8 position tool changer. Allows: cutting panels, milling, nesting, drilling, engraving, cutting foam.

CNC NESTING WORKING CENTRE PROFIT H10 19.38 FORMAT-4: allows panel cutting, drilling and milling in any shape desired, all in one process.

CNC Cutting

- Load panel, start working. Once loaded, the profit H10 works without an operator. No additional programing is required.

- Freeform shaping cut: any shape possible

- Minimum material waste thanks to CNC Nesting technology

- Highly precise cut edges, shaping cut = format cut, processed items are immediately ready to be processed on an edgebander without a premilling unit

CNC Drilling

- Material does not need to be processed further by a CNC or drilling machine

- Significant time savings thanks to a combination of CNC cutting and CNC

drilling in just one work cycle - Workpieces are fitted with bore holes or rows of bore holes before or after the shaping cut

- Processed items are immediately ready for processing on an edgebander

CNC Nesting

- Any desired shape can be used. Minumum waste thanks to nesting software

- Significant time savings thanks to a combination of CNC cutting, CNC drilling and CNC nesting in just one working cycle

- Workpieces are fitted with bore holes or rows of bore holes before or after the shaping cut

- Processed items are immediately ready for processing on an edgebander

CNC Milling

- Matrix table can be fitted with

vacuum pods; CNC milling operations can be carried out just as in standard CNC machines - Up to 36 tool slots available for CNC milling

TECHNICAL DETAILS

Nesting table: working area X= 3720 mm, Y= 1860 mm, Z= 105 mm

Quick and easy positioning of the vacuum pods, suitable for every workpiece size: The matrix geometry of the matrix table makes handling and positioning the vacuum pods easy. Additionally a distributor can be used, to establish a dual-circuit vacuum system.

Tool change: The linear tool changer ensures a rapid tool change and minimises the compressed air consumption. This enables the use of aggregates that have larger tool diameters for increased performance of your profit H10. Up to 36 tool and aggregate positions are available.

Drilling head: Regardless whether the machine will only be used for cabinet manufacturing or as an all-rounder. You decide which drill-head configuration is the right one for you. Choose between, a head with only vertical drilling spindles or spindles with a grooving saw for vertical and horizontal processing.

Length measurement system: Setting the parametres of your tools made easy: every tool length is stored in the tool database accurately to one hundredth of a millimetre.

Doors: The C-axis enables highest flexibility and the optional use of units. Complete processing of doors in the shortest processing time is possible.

Chip deflector: The interpolating rotary motion of the chipping deflector is controlled via the C-axis. Thus, the resulting chippings are guided in the direction of the extraction channel, especially with processing edges.

Cutting foam: The large Z-direction stroke enables the use of special units. Any type of foam up to 80 mm can be processed in highest quality.

Lamello: By using the 5-motionplus units, manual angle settings are a thing of the past. Tools, such as the Lamello spindle moulder tool can be used.

Template: Using the template connections on the left or right sides of the matrix table, you can extend your application spectrum. The template connections ensure maximum vacuum performance, even with small contours.

3D-Milling machine: Simplest 3-axis application with impressive results. There is no limit to your creativity.

Edge processing: Block vacuum pads for edge milling on the bottom side of the tool. The horizontal drilling unit can be used without limit.

Engraving: Your future field of application is not only limited to wood. Special equipment features also allow the processing of Alucobond.

Screw taps: Metric threads or fine threads. Simple programming - perfect results

To request information about this product, you can do so in the following ways.